[ad_1]

Compliance, compliance, compliance. It’s a word everyone in the cannabis industry has to consider daily.

Compliance regulations are largely a positive thing for consumers, ensuring products are accurately labeled, sufficiently packaged, and safe from small hands that may mistake a THC-infused gummy for a piece of candy.

However, some regulations render the manufacturing and packaging process excessively time-consuming.

They also limit the creative freedom of labeling most other industries enjoy. The myriad compliance obstacles can ultimately lead to a reduction in profits, something no business wants to experience, no matter how consumer-focused it is.

But, on rare occasions, compliance, consumer benefit, and positive profit margins can be achieved in one fell swoop.

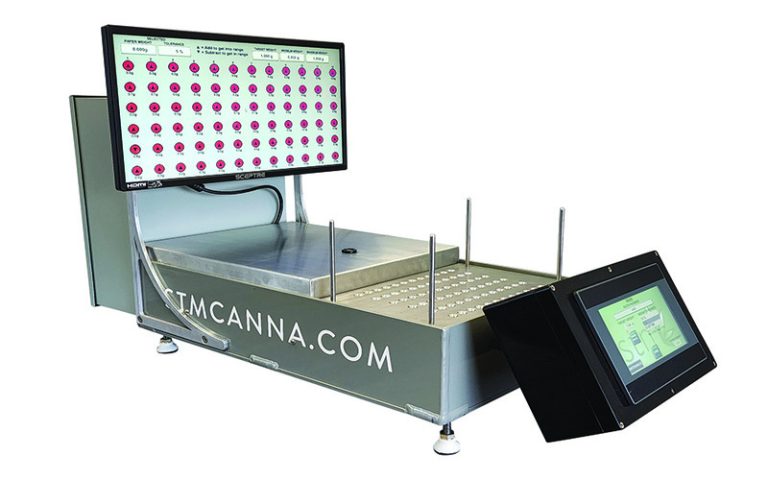

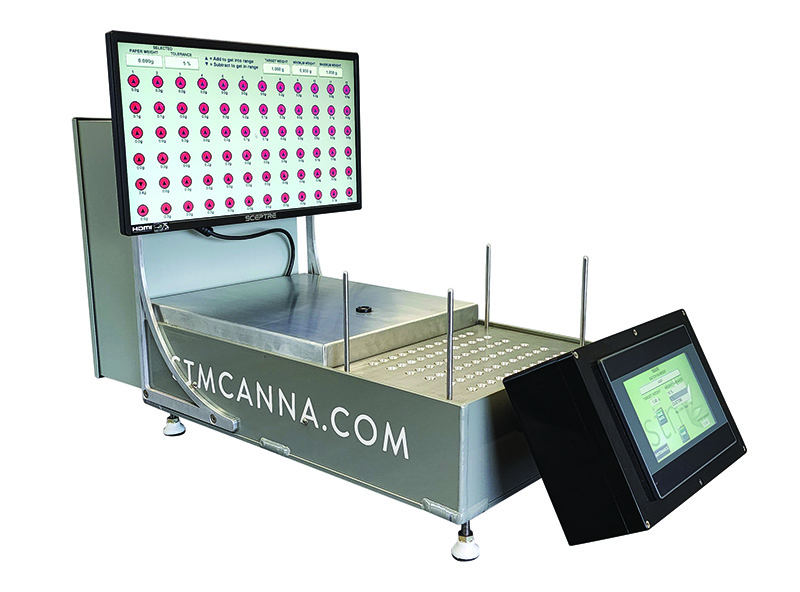

STM Canna Launchpad Weigher

This is where the STM Canna Launchpad Weigher comes in. Specifically designed for weighing pre-rolled joints, the scale ensures a precise weight reading for each individual pre-roll to below a 5% tolerance.

Compliance regulations are met for every pre-roll, manufacturers can be sure they are not losing product on overweight joints, and consumers receive exactly the amount of flower promised on the label. It’s a win-win… win.

The Launchpad also gives operators the ability to identify rejects instantaneously via an easy-to-read color-coded display.

With a simple-to-use interface, operators can find a scale’s parameters by selecting the target pre-roll and paper weight for proper taring, and most importantly, the desired tolerance percentage.

With the module’s ability to weigh 72 joints simultaneously within seconds, labor costs can be significantly reduced for businesses at any scale.

Easy as 0.1, 0.2, 0.3

The ability to maintain precise quality control over the weight of your pre-rolls and maximize profits attributed to under or over filling is a game changer for pre-roll manufacturers.

It is also simple to use, so anyone on the factory floor can use it with a small amount of training.

First, a tray of nicely packed joints is taken out of the STM Rocket Box or other pre-roll machine and placed into the Launchpad.

After a pre-roll size is selected, the target weight and weight tolerance percentage can be added on the touchscreen.

The large heads-up display will then tell the user if the joints are within the selected weight tolerance.

Finally, adjustments as necessary to the joint or Rocketbox settings if any pre-rolls are under or overweight and save the batch data to export later.

This step ensures future packs can be done consistently, reducing the time taken in each step of the process.

The STM Launchpad functions as a stand-alone machine or better as part of STM Canna’s precise workflow.

The Launchpad and companion modules such as the Rocketbox and Atomic Closer are designed with a small form, high impact footprint to maximize facility space and production output.

STM’s fully modular system enables expansion and scalability as a company’s needs grow.

[ad_2]

Source link